In applications where the scan target is larger than a single sensor’s field of view, or has a complex shape, multi-view scanning and processing are required in order to capture the complete geometry of the part.

Multi-view scanning and processing are used to:

Cover larger fields of view while maintaining high resolution

See more of the part (360º ring layout or opposing layout to measure thickness)

See past occlusions (undercuts, gaps, steep edges)

Perform absolute measurement between two or more features separated by a large distance (where both sensors must be calibrated to a world coordinate system)

Multi-View Processing in Gocator®

What makes Gocator® unique among 3D sensors is its built-in multi-view 3D scanning and processing capability, which can be executed in one of two ways:

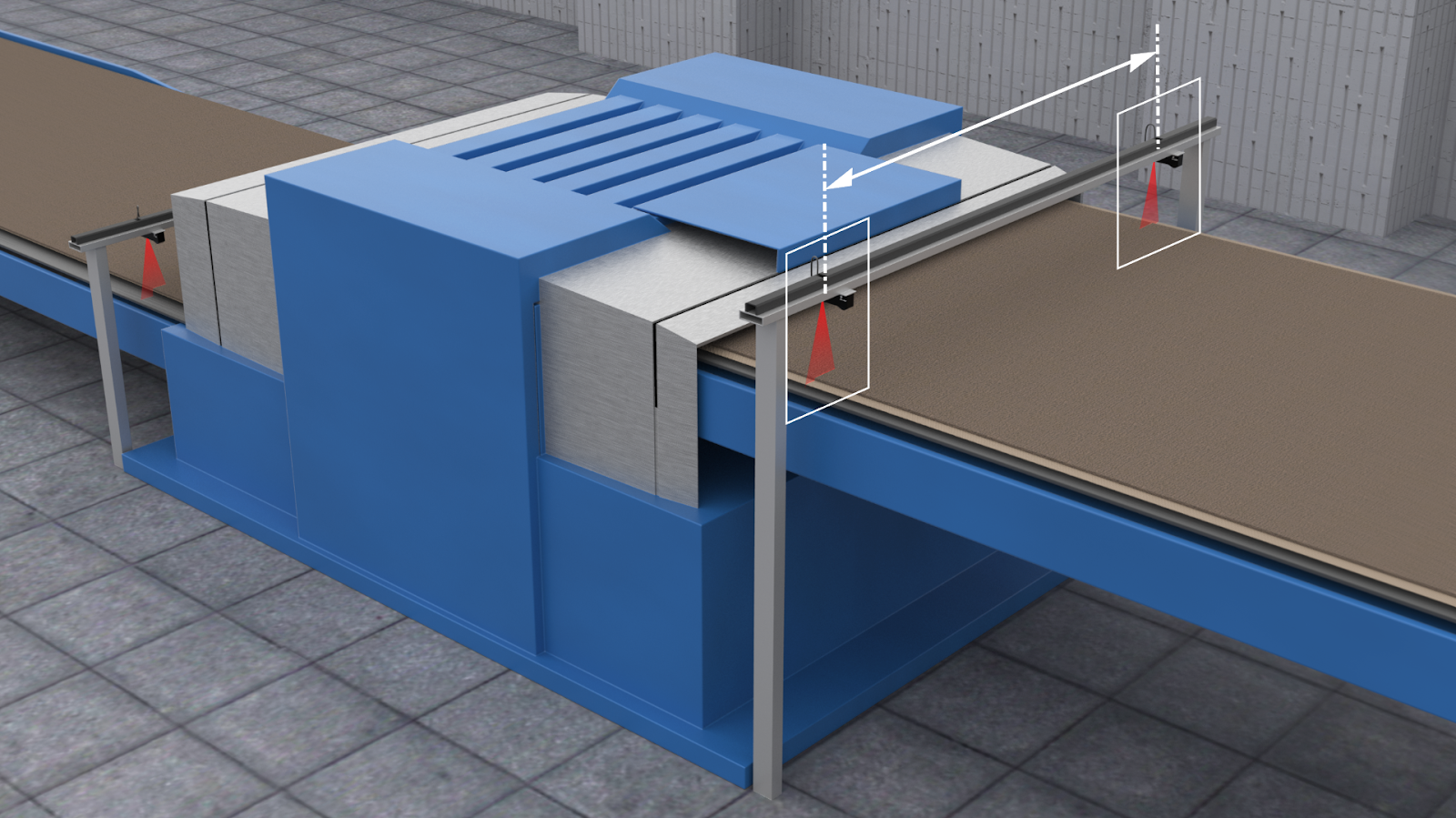

Using multiple networked sensors to scan all the different views of a part to build a fully digitized 3D model

Using an XY stage and a single sensor to scan and stitch several views into a single surface

And that's just the beginning of the story ...

Stay tuned for part 2 next week, when we’ll cover the details of multi-view 3D scanning and processing using sensor networking.

Find more information about LMI Gocator here: https://lmi3d.com/products/gocator-3D-smart-sensors

Find more information about Machine Vision here: http://advanceultravision.com/

Multi-view scanning and processing are used to:

Cover larger fields of view while maintaining high resolution

See more of the part (360º ring layout or opposing layout to measure thickness)

See past occlusions (undercuts, gaps, steep edges)

Perform absolute measurement between two or more features separated by a large distance (where both sensors must be calibrated to a world coordinate system)

Multi-View Processing in Gocator®

What makes Gocator® unique among 3D sensors is its built-in multi-view 3D scanning and processing capability, which can be executed in one of two ways:

Using multiple networked sensors to scan all the different views of a part to build a fully digitized 3D model

Using an XY stage and a single sensor to scan and stitch several views into a single surface

And that's just the beginning of the story ...

Stay tuned for part 2 next week, when we’ll cover the details of multi-view 3D scanning and processing using sensor networking.

Find more information about LMI Gocator here: https://lmi3d.com/products/gocator-3D-smart-sensors

Find more information about Machine Vision here: http://advanceultravision.com/